Electrostatic Precipitator

Rhajtek specialized in services related to electostatic precipitator-a sophisticated pollution control device that relies on a triad of factors—process, mechanical, and electrical—to effectively mitigate air pollution issues stemming from industrial operations.

What is a Electrostatic Precipitator (ESP)?

An electrostatic precipitator (ESP), is a sophisticated pollution control device that relies on a triad of factors—process, mechanical, and electrical—to effectively mitigate air pollution issues stemming from industrial operations.

ESPs are pivotal in adhering to stringent environmental regulations, a necessity for modern plants. Compliance with these regulations necessitates capital investment to implement modifications or upgrades crucial for the ESP to meet performance expectations.

In some instances, plants may undergo changes in their processes, such as increased capacity, shifts in fuel type, or changes in products produced. These alterations can pose challenges to ESPs, leading to subpar performance that falls short of expectations. To enhance the performance of electrostatic precipitators and ensure regulatory compliance, a thorough evaluation of the equipment based on the three critical factors is imperative. Rhajtek Industrial Systems & Construction, with their specialized expertise in this field, plays a vital role in guiding these evaluations and implementing necessary improvements to guarantee effective air pollution control and maintain compliance with environmental regulations.

How ESP Works?

Rhajtek serves as your one-stop solution for essential internal components required to ensure the optimal functionality and structural integrity of baghouses, which are vital in air pollution control systems.

Electrical Optimization Evaluation

Process changes affect the performance of the electrostatic precipitator. These changes can impair the level of efficiency the ESP can perform. These changes could be of the following:

- Changes in fuel type i.e. coal with high sulfur content, with low sulfur content, use of alternative fuel, etc.

- Increase in production capacity thus increasing the amount of flue gas on the system

- High fly ash conversion of the fuel

- Equipment modification i.e. boiler modification, SCR installation, etc.

- Increase dust resistivity due to change in temperature.

- Increase flue gas capacity thus lowering the SCA (specific collecting area) ratio of the ESP.

Evaluation of the existing electrostatic precipitator based on the process changes is important in analyzing the capability of the equipment. These will also dictates the proper size of the ESP needed to comply with the regulations.

Mechanical Optimization Evaluation

Mechanical aspect of the electrostatic precipitator plays an important role on the performance of the unit. Mechanical parts of the ESP deteriorate over the period time thus causing low performance of the ESP. There are also several factors that affect the mechanical components of the ESP that leads to poor performance. These are the following:

- Thermal expansion of the internals

- Gas distribution of the flue gas across the precipitator

- Bending or bowing of collecting plates and discharge electrodes causing close clearance problem.

- Poor material selection.

- Inefficient cleaning mechanism

- ESP size not enough for the requirement

- Increase gas flow due to increase in capacity reduces the size of the precipitator.

In order for the Electrostatic precipitator to perform efficiently, there are needs to maintain the integrity or the soundness of the mechanical components. But first, there is a need to evaluate the unit whether the size is enough to handle the process inputs as well as the required outlet emission. With this, it is easier to analyze whether the ESP can handle the load or not. If the ESP units are sized properly, then poor performance could be due to the mechanical problems. This can be analyze based on the information as well electrical inputs to be provided by the plant and the actual inspection to be done on site during outage.

Electrical Optimization Evaluation

Over the years, developments of new technology for the automatic voltage controllers are continuously revolving. State of the art controllers are now being developed to further improve the collection efficiency of the electrostatic precipitators. Old controllers do not have the features that the new controllers have today. Improvements on the controls can further develop or improve for better collection of the electrostatic precipitator without any changes on the mechanical side of the precipitator even with the changes made on the process side.

Performance Optimization

Considering all the factors specified above, performance of the precipitator could be improved based on the inputs on all the aspects indicated above. Summarizing this information will be of great help in determining the best possible solution for the electrostatic precipitator improvements.

RHAJTEK INDUSTRIAL SYSTEM provides the solutions for all aspects of the electrostatic precipitators, perform the evaluation of the electrostatic precipitator based on the process, mechanical and electrical aspects that affect the performance of the electrostatic precipitator and performs upgrade of existing units that will increase the performance and reliability of the equipment

Gas Flow Study

Gas Flow Distribution is very important as it significantly affect performance of the electrostatic precipitator. Oftentimes, this issue or problem are being neglected in the plant and concentrate more on troubleshooting other issues/problems.

If gas flow distribution across the precipitator is a problem, it cause lower than predicted collection efficiency of the precipitator even though all internal components are still in good physical conditions.

Problems associated with Gas Flow Study

- Lower than predicted collection efficiency of the precipitator

- Excessive sweepage or re-entrainment of dust in the precipitator

- Excessive sparking on the low velocity zone

- Dust falling out plugging the distribution device

- Inlet distribution devices are already worn out and holes are not the sizes as it was during original installation

- Some of the corrective plates were worn out or fall off

- Deformed inlet distribution devices

- Build up on the distribution device

Impact of Poor Gas Distribution

- The improved collection efficiency on the low velocity zone does not offset the degraded performance on the high velocity zone

- Dust build up occur in low velocity zone thus creating excessive sparking

Objective

The objective of the Gas Distribution Flow study is to identify actual gas flow distribution across the precipitator and to achieve acceptable uniformity at the minimum pressure drop during correction

Actual Gas Distribution Flow Study

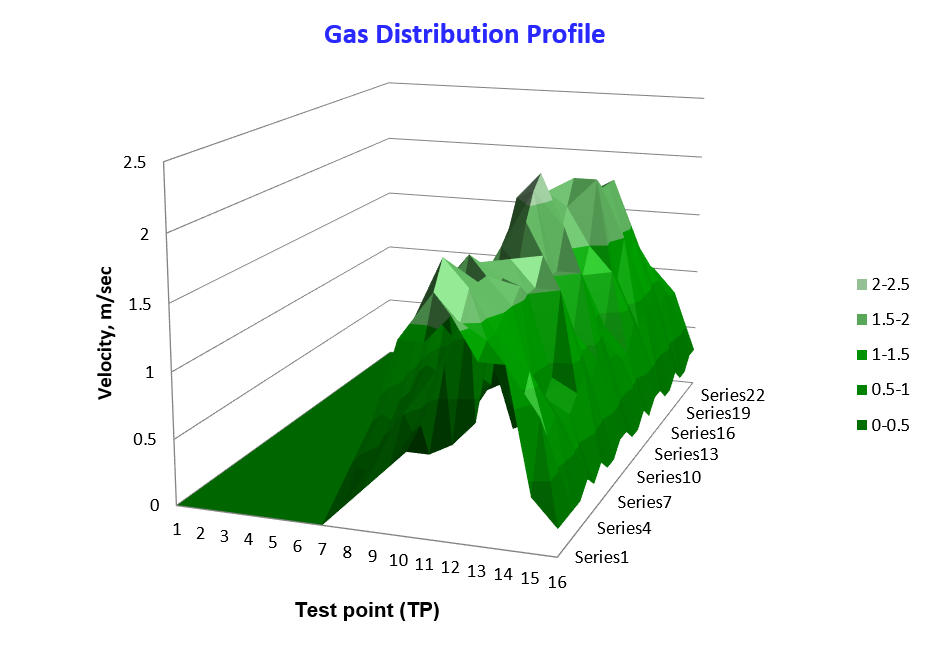

Gas distribution flow profile shown on below graph is an actual measurement done in one of the cement plant that show uneven gas distribution across the precipitator. Graph shows flow of gas on top is minimal as compared to the bottom area. Corrections were made after the measurement and there was a significant improvement on the collection efficiency after the corrections.

ESP Components

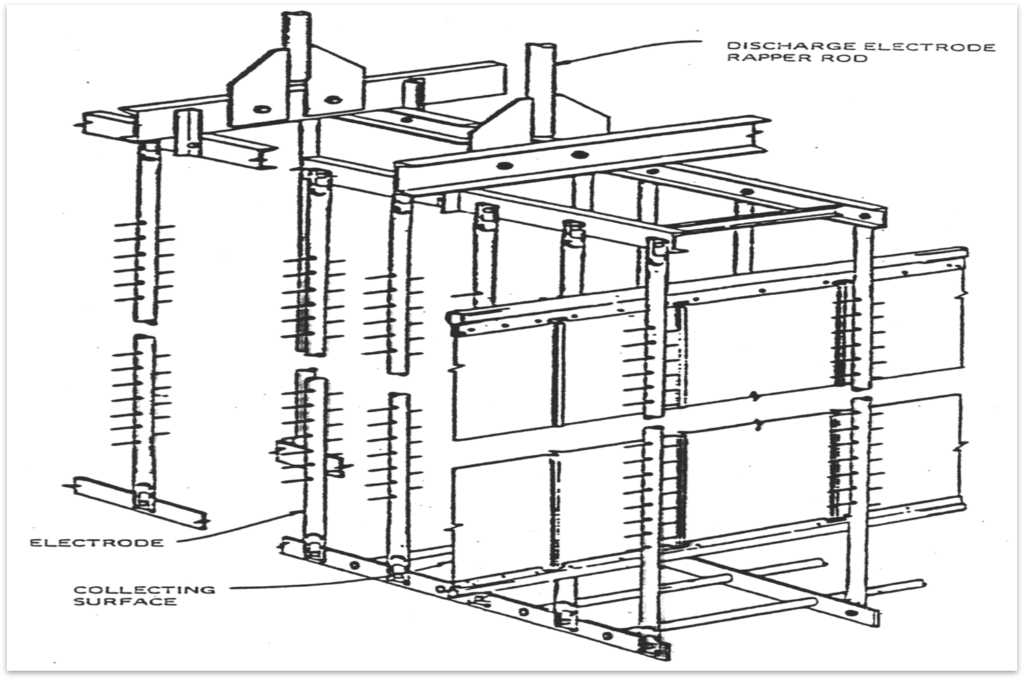

All ESP regardless of particular design, contain the following components:

Chambered Unit

Single Chambered Unit

Multi Chambered Unit

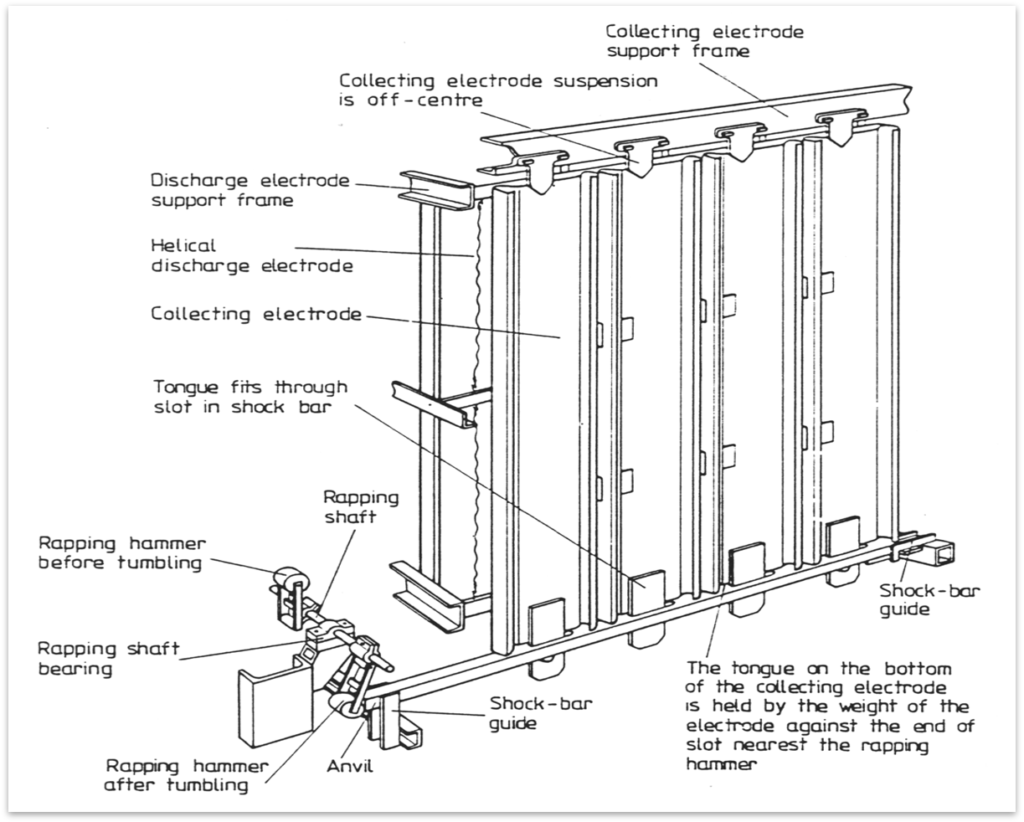

Discharge Electrode System

Rigid Mast Frame -DE Wire Type

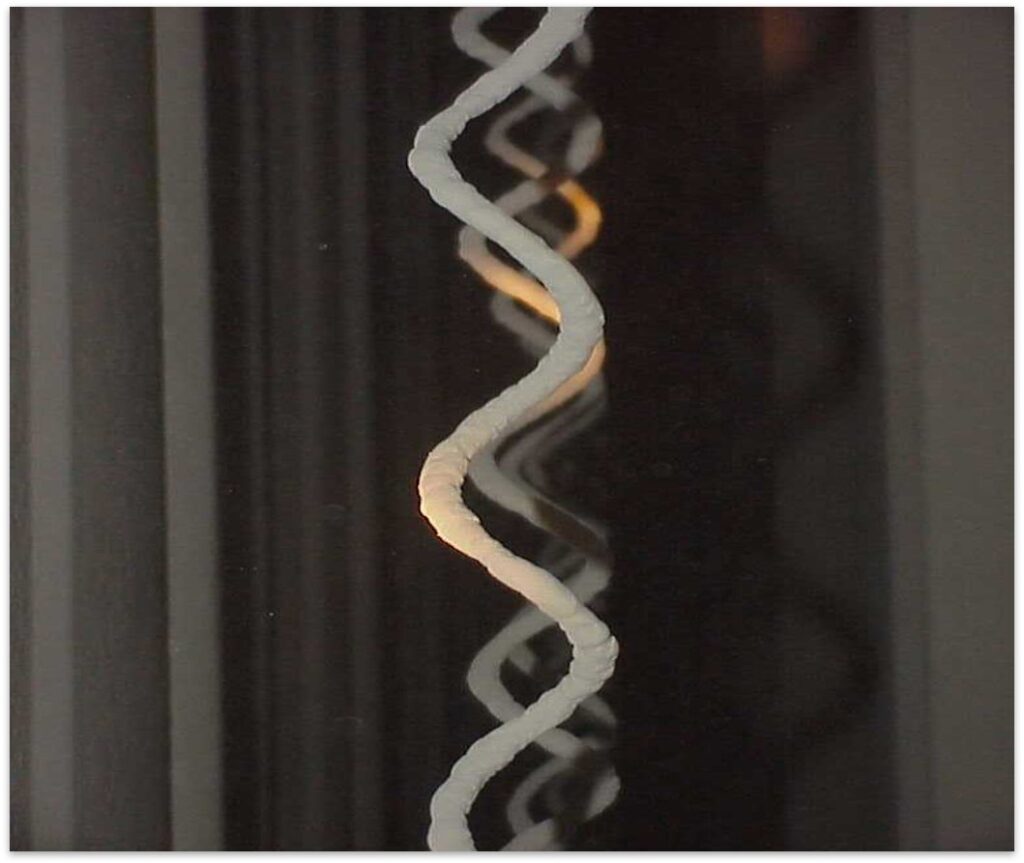

Rigid Mast Frame -DE Spiral Type

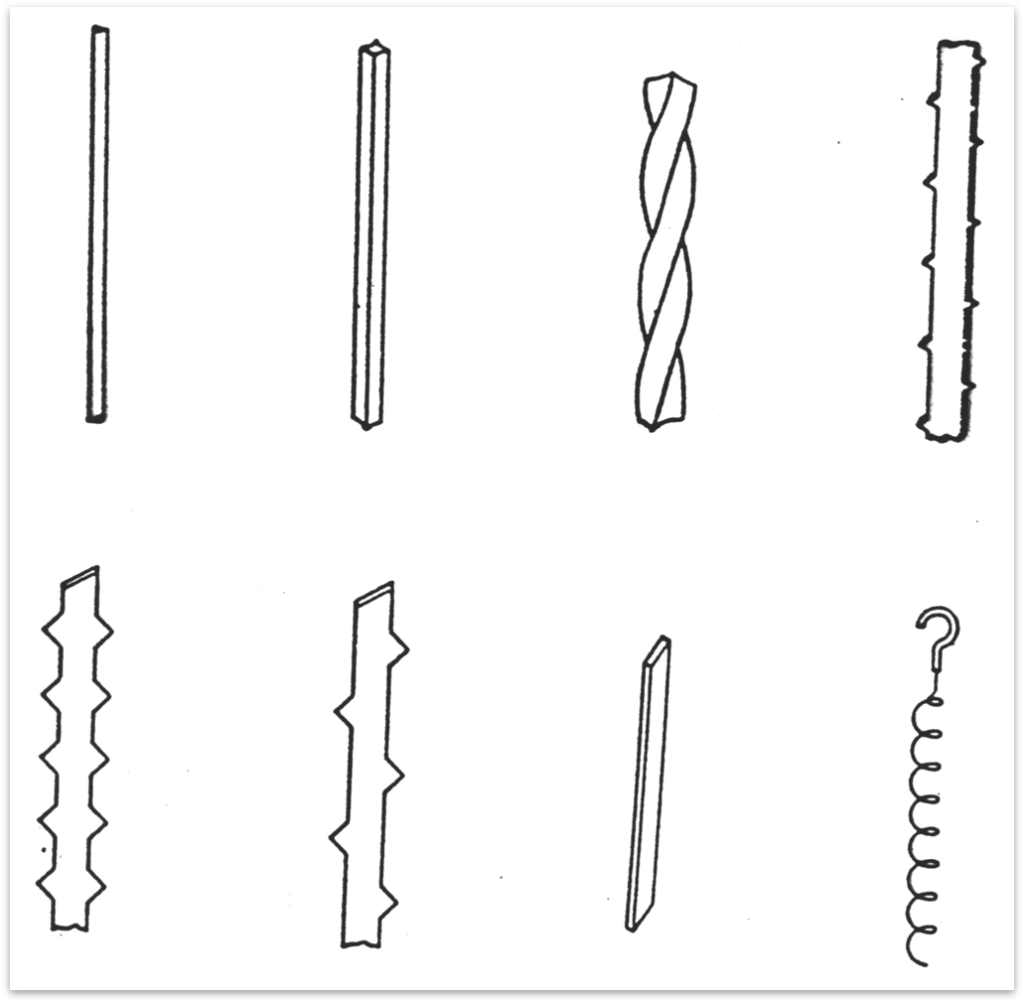

Rigid Discharge Electrode Design

- Wires

- Isodyn

- Twisted Wire

- Barbed Wire

- Spiral Wire

- Flat Wire

- Rigid Discharge

- Rigid MastFrame

- Duratrode

etc…

Collecting Electrode System

High Voltage Electrical System

T/R Sets

Electrical Controllers

HV Support Insulators

Hoppers/Discharge System

- Types of Hoppers: Pyramid & Trough

- Discharge System ( Pneumatic, Screw Conveyors, Rotary air lock and Chain conveyor

Rappers/Cleaning Mechanisms

Impact Rappers

Tumbling Hammers

Shell Casing

Rhajtek Shell casing, with its variable design, can come in different configurations such as weather enclosures, penthouses, and multi or single chambers.

SERVICES

ESP Technical Services

Transformer/Rectifiers

- Transformer/Rectifier basics

- Transformer, Rectifier

- Choke coil

Inspection & maintenance - Gauges

Fluids Megger tests, bushings and connections - Switches

Maintenance log - Dissolve Gas Analysis

- Perform leak and pressure test.

- Perform Megger/Insulation Resistance test.

- Record P.I (Polarization Index) between phases and ground.

- Perform open-circuit/ core loss test on all phases.

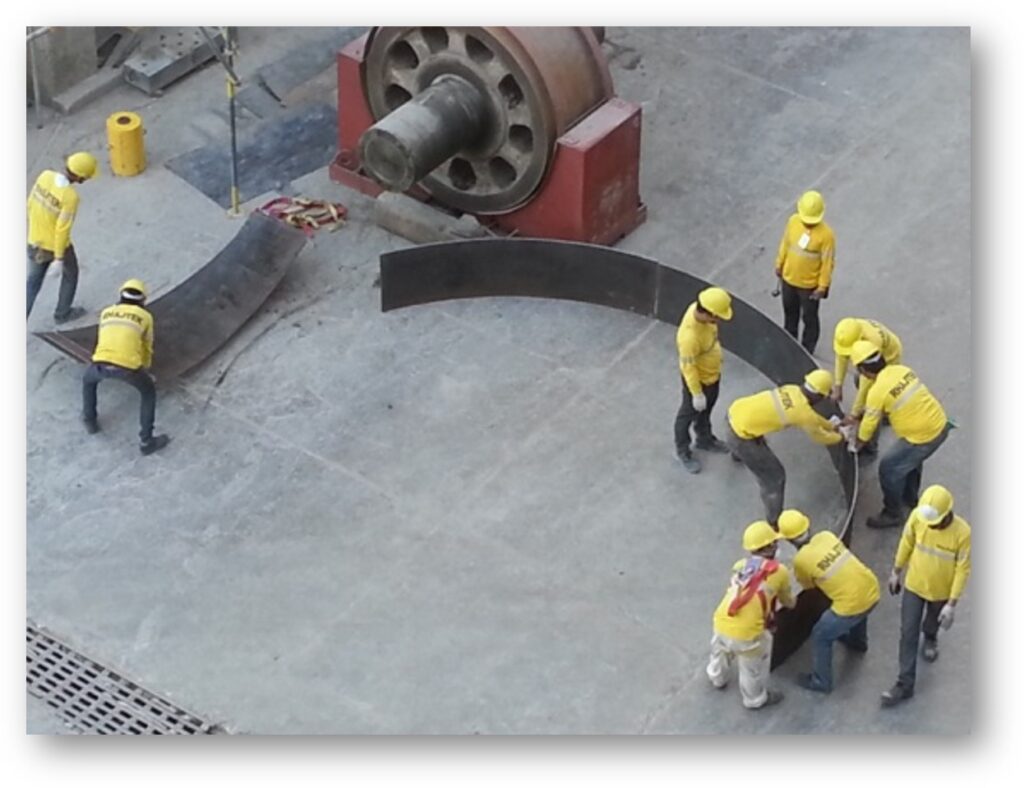

ESP Repair and Maintenance

RHAJTEK highly trained service crew provides services for Electrostatic Precipitator repair, maintenance, upgrades and new installation.

Our maintenance program includes preventive maintenance, repair and an annual service contract to maintained all Electrostatic Precipitator unit and aim to minimize cost of our customers in terms of unexpected shutdown and replacement of internal components.

Ready to unlock your industry full potential and scale for decades of success? Let’s make it happen!

Click below and let’s turn your dream engineering solutions into reality today!